Cutting systems

Cutting systems

In the plastics industry or in injection molding production, component removal is often not the only challenge. In subsequent processes, the product often has to be separated from the sprue. We are already at your side as a partner in the development phase and support you in the design of your mold concepts and in the planning of operating resources. High follow-up costs due to subsequent mold changes can thus be prevented. With our solutions in the area of sprue separation and expertise in the development and design of individual cutting concepts, we realize technically and qualitatively demanding projects - we are ready to precisely cut a wide variety of materials with our cutting and punching devices.

Cutting technology

In the cutting technology product area, we can offer you a wide range of different products such as sprue cutters (manual/automatic) in various sizes, a large range of cutting inserts and standardized punching and lifting units. If the producibility with the standard solutions is not given, we can fall back on alternative cutting concepts.

Product range:

- Cutting inserts

- Automatic/manual nipper bodies

- Knives/blades

- Air nipper holder

- Lifting units

- Standardized punching units

- General cutting accessories

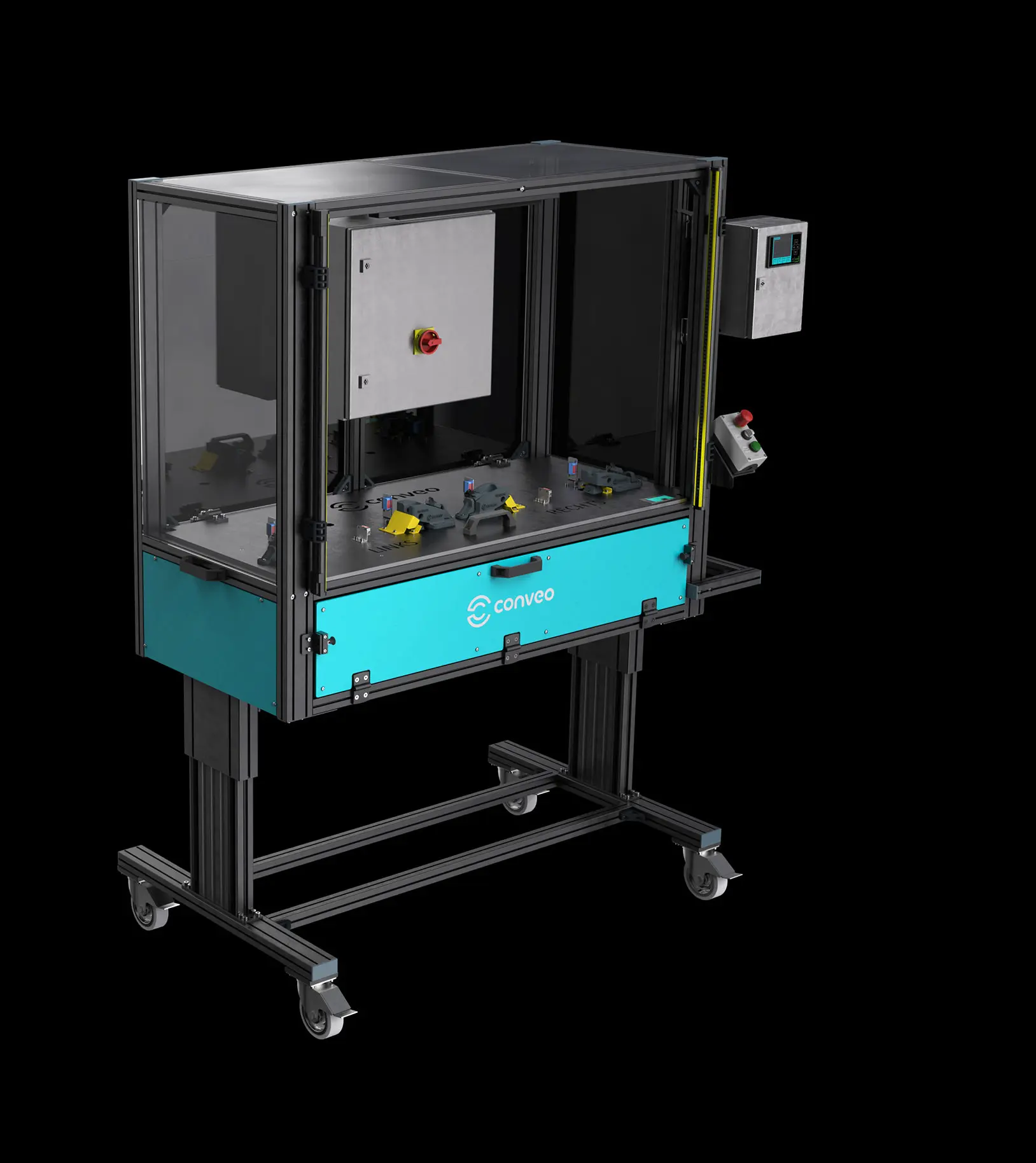

Self-sufficient cutting stations & special solutions

If, due to the process, a standard solution or manual cutting is not sufficient or does not meet the qualitative requirements, then our self-sufficient cutting stations or special machines are the right solution to make your processes more productive, safer and more efficient.

Product range:

- Autonomous cutting stations

- Hot cutting systems

- Ultrasonic cutting systems

- Fully automatic cutting systems with robotic solution

Questions & Answers

Which parameters are important for the layout of the cutting concepts?

What materials can be cut?

Are there alternatives to punching or cutting?