Robotic Gripping Systems

Robotic Gripping Systems

With our standardized modular robotic gripping systems and our expertise in the design and development of special gripping systems, we always have the right solution for your application.

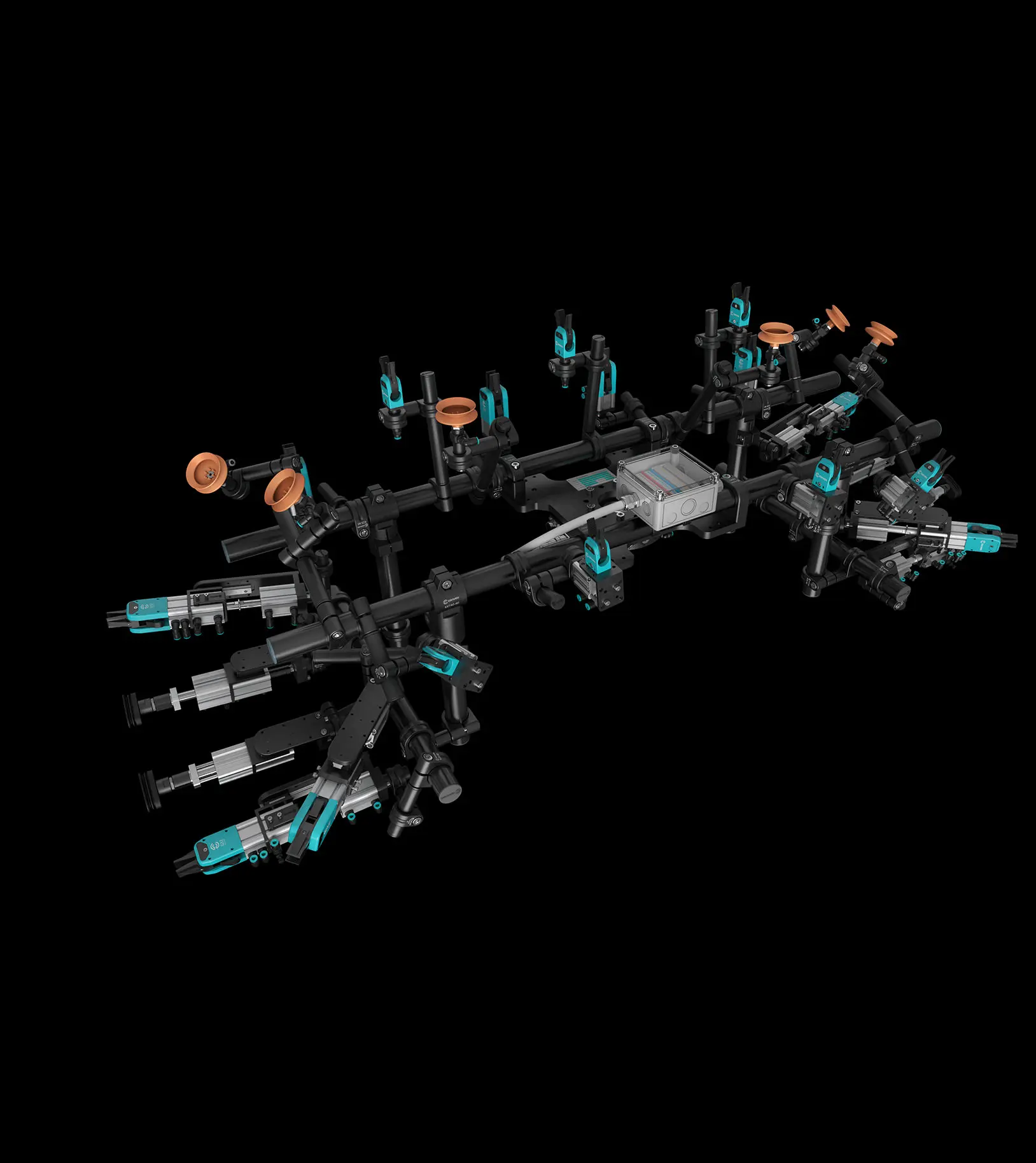

Modular system – tubular

Our tubular modular system can be used flexibly, and, with its 360° degree of freedom, it is ideally suited for process-reliable removal or handling of "geometrically complex components". In addition, the simplest applications can also be mapped with the tubular system. Contact us - we will check which system is the right one for your application.

Advantages:

- Easy assembly

- High flexibility - 360° degree of freedom

- Time saving during commissioning due to high flexibility

- High frictional connection due to larger clamping surface.

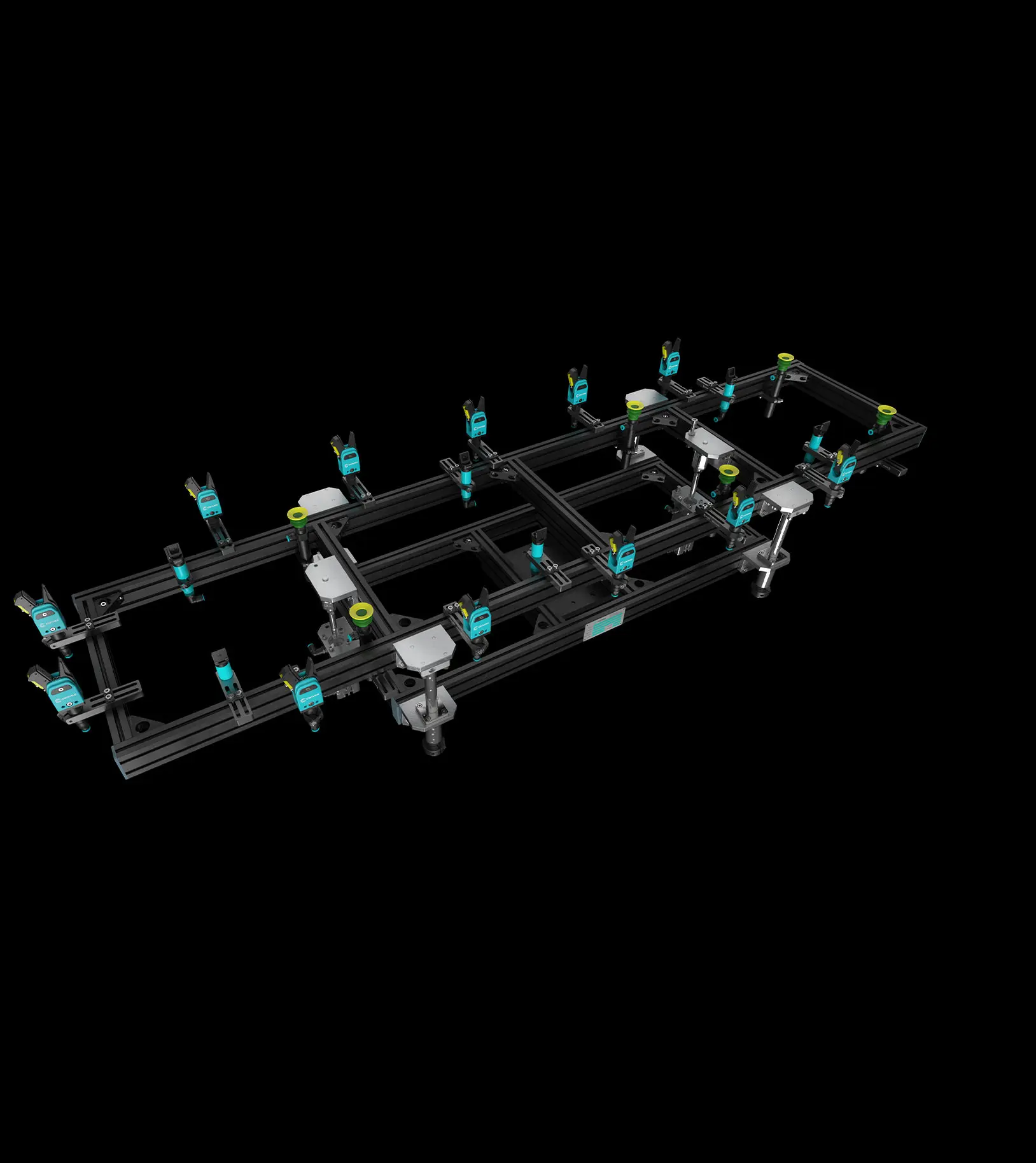

Modular system – Square

Our square modular system is characterized by flexibility and robustness and is compatible with systems commonly used in the industry. The square profile system is particularly suitable for the removal of “simple-geometry components", but complex removal situations can also be mapped. Contact us - we will check which system is the right one for your application.

Advantages:

- Compatible with systems commonly used in the industry

- Easy to use

- Flexible range of application (fixture construction, etc.)

- High bending stiffness

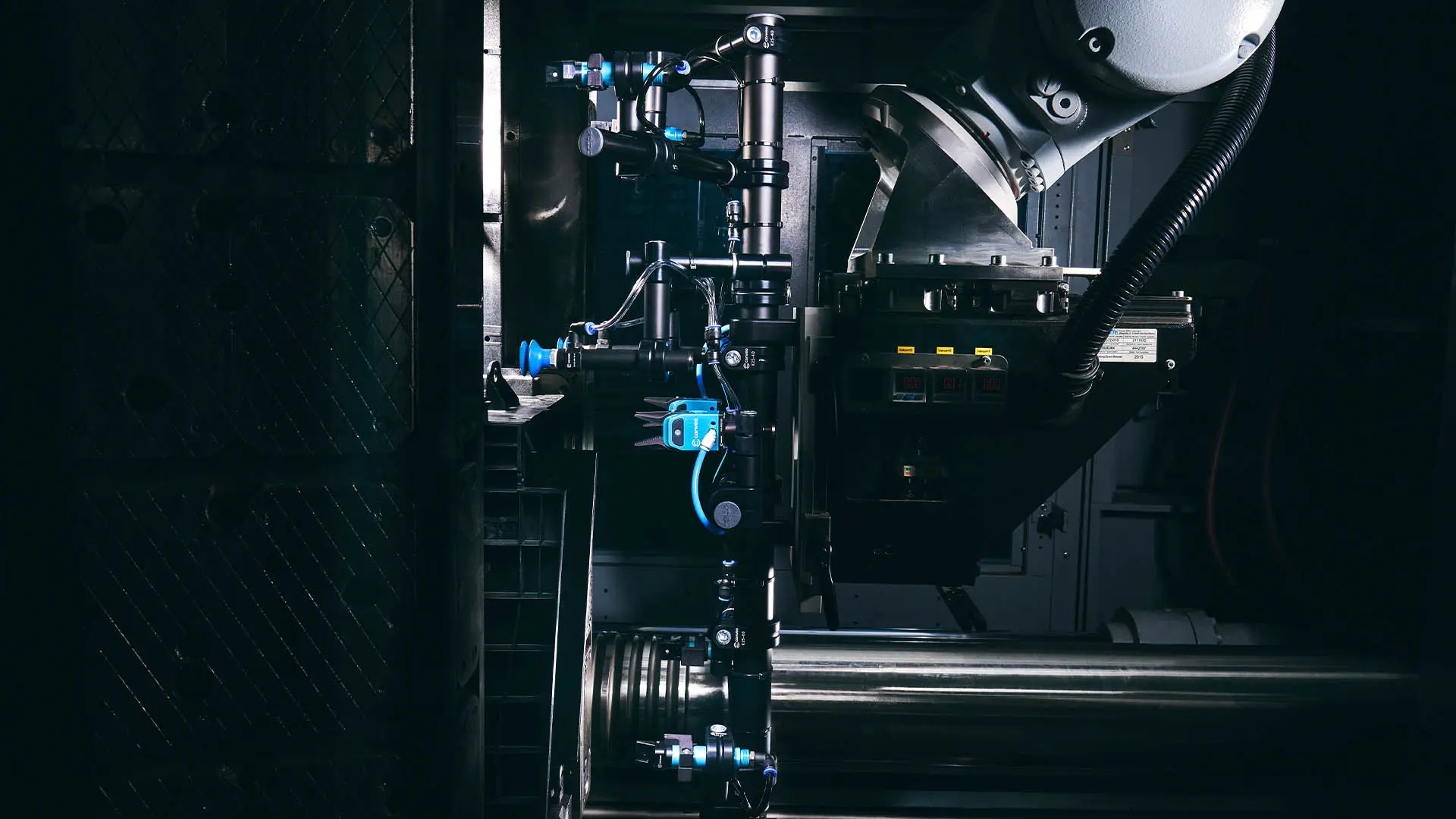

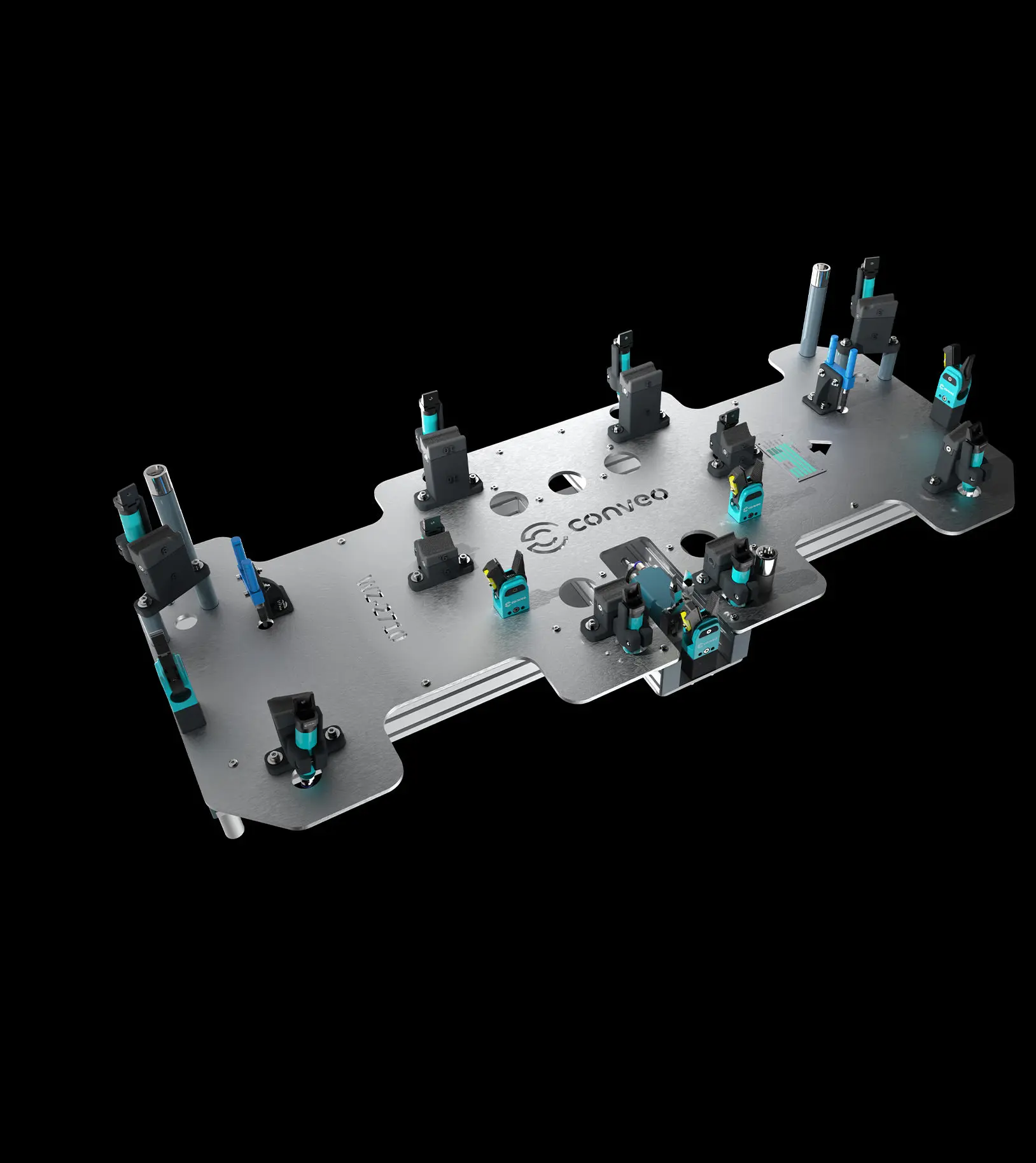

Special gripper system

Gripping systems are used in a wide variety of applications and industries. Whether handling solution, assembly application or lightweight system, with our expertise in the design and development of special gripping systems, we will always find the right solution for your application. Using the latest technology, such as 3D printing, we are able to respond individually to your needs.

Questions & Answers

When should I use which system?

How can I handle/grip sensitive surfaces?

Can I also build my gripper myself?

Which materials/products can be gripped?